The equipment used in the printing industry has always been of our attention. We are discussing the sale or purchase of a used Gallus EM 280 with 6, 7, or 8 groups of printing. A used Gallus EM 280 printing press is ideal for the efficient production of high-quality self-adhesive labels in small to medium runs. It is easy to operate, allows flexible use, and a quick combination of printing processes. It can be enhanced with a rotary screen printing system, embossing, rotary stamping, and folio printing.

Do you want to buy a Gallus EM 280?

If you are interested in purchasing a used Gallus EM 280 equipment with 6, 7, or 8 printing groups, we can send our offers for flexographic printing machines of this type that are available for sale at the time of submitting your request.

Please send us your requirement and specify as many details as possible about the used Gallus EM 280 printing press you are looking for. In this way, we will find the best offer for your company’s needs. Here are the details that help us in this endeavor:

• What is the maximum number of operating hours accepted.

• What are the manufacturing years of interest.

• If you want it to have automatic settings and registry control.

• If you want it to be equipped with rotary die-cutting units (it would be useful to specify the desired number as well).

• If you want it to have other specific characteristics: have a drilling system, folio application, embossing, etc.

The more details you give us about your needs and expectations regarding the used flexographic equipment you want, the easier it will be for us to offer you the best options. Please also let us know if you are interested in machines that are in stock or only used Gallus EM 280 equipment in production, if you are looking for printing presses that have been overhauled and cleaned, or if it is ok and in “as it is” condition.

Do you want to sell a used Gallus EM 280?

If you have used such equipment for a period of time, and now you want to sell it as quickly as possible to buy a new, better-performing one, all you have to do is contact us and provide detailed information about the used flexographic printing machine you own.

Please send us the following details about the used Gallus EM 280 equipment you wish to sell:

• What is the number of hours of operation?

• What is the condition of the machine?

• Is the equipment in production or in stock?

• Are there functionality issues on various components? Has it undergone repair work over the years? What parts were replaced?

• What is the year of manufacture?

• What is the machine equipped with?

• What is the price? Is it fixed or negotiable?

• Other details about the equipment that you think are important.

Features of a Gallus EM 280 printing machine:

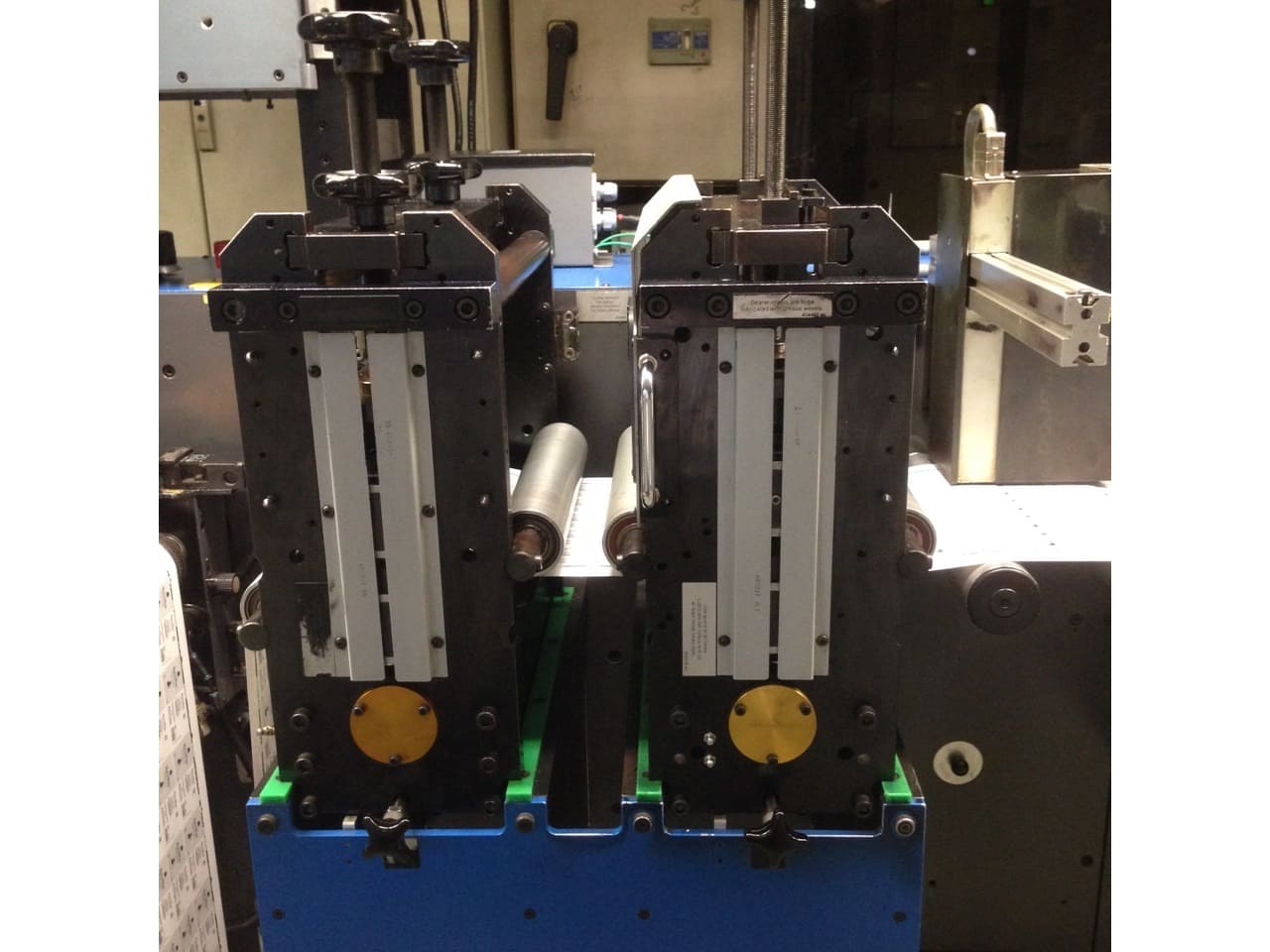

• It is a modular and compact flexographic machine that can be quickly configured.

• It has a high level of specialization, and labels with various characteristics can be printed.

• There is a quick-change printing unit platform for switching between flexographic, screen printing, embossing, and folio printing.

• Setup times are short and waste is minimized thanks to modern technologies.

• Offers a wide range of processing solutions such as rotary stamping, die-cutting, foil printing, and lamination.

• The operation is based on a touch screen that memorizes the work data (this is of great help, especially in the case of repetitive work).

Other important details about the used Gallus EM 280

Used Gallus EM 280 machines, regardless of the number of printing units with which they are equipped: 6, 7, 8, or more colors, if they are water-based or UV inks, are printing equipment with fairly low operating costs and they can print a multitude of adhesive labels in very good quality conditions. These models of flexographic machines produced by Gallus are easy to operate, and stable during printing, changing settings between the different models of labels being printed is done in a fairly short time and offers the possibility of using several types of printing methods and many types of finishing.

The maximum mechanical printing speed of a used Gallus EM 280 is 150 m/minute, and the maximum width of the reels to be printed can be 280 mm. If we are talking about the maximum width and length of the areas that can be processed, these parameters depend on the type of process:

• Flexographic printing – maximum width: 280 mm, maximum length: 457.2 mm, minimum length: 203.2 mm

• Rotary screen printing – maximum width: 270 mm, minimum width: 130 mm, maximum length: 533.4 mm, minimum length: 269.9 mm

• Embossing and folio printing: maximum width: 280 mm, maximum length: 552 mm, minimum length: 290 mm

Gallus EM 280 machines can print self-adhesive materials and paper starting from 60 g/sqm as standard equipment.

These used Gallus EM 280 flexographic equipment can be equipped with UV drying systems: GEW, IST, Ray, or other type on each group, BST camera for inspection during printing, Corona system, automatic setting system, and control of Sensotec registers, unit stamping unit, embossing and foil application unit, lamination system, Teknek cleaning system.

Usually, when selling a Gallus flexo machine, the printing house also includes in the sales package the printing, magnetic, and anilox cylinders that were used on that machine.

Processes that can be integrated within the Gallus EM 280 machine

Flexography

Flexography is a printing process used to print on almost any type of substrate, such as plastic, cellophane, paper, or metal films. This process was first created for printing cardboard packaging, but today’s technology has evolved so much that it also allows the printing of labels, foils, etc. With the help of flexo printing machines, such as the used Gallus EM 280, it is possible to create printed works with a high resolution and a high quality of printing, quite close to that obtained by offset or rotogravure.

The flexographic printing process can be performed on both absorbent and non-absorbent materials. The high print speed ensures high productivity – this is a major advantage especially in the case of high-run jobs because they can be completed in an extremely short time. It is possible to print jobs in 6, 7, or 8 colors, depending on the printing units with which the equipment is equipped. Flexography allows the application of special inks (for example: metallic or fluorescent) and the realization of finishes such as lamination, application of hot or cold foil, embossing, application of holograms, etc.

Screen Printing

The main difference between flexography and screen printing is the printing process. In the case of flexography, photopolymer plates are used to transfer fluid ink to the substrate to be printed, while screen printing involves the transfer of inks to the substrate using a squeegee and screen of different densities. Screen printing gives labels elegance through embossed elements and strong colors. Among the most important advantages of screen printing are: perfect opacity (the inks used in the screen printing process have good coverage of the printed surface), obtaining different textures by applying varnishes with special effects, and the high resistance to UV rays of the labels.

Folio printing

Folio printing is the addition of gold or silver elements to the surface of the labels to achieve premium finishes and a spectacular end result. The process itself is simple and involves the application of pressure between the film and the substrate to be printed. It can be done cold or hot.

Embossing

Embossing is a dry and permanent printing method, resistant over time. The characters embossed on the surface of a label remain there for a long time and deteriorate over time. In the printing and packaging manufacturing industry, embossing adds luxury and sophistication. A label with an embossed finish can build memorable visual and tactile experiences and is a great way to stand out.

If you are a buyer looking for a used Gallus EM 280 printing machine, do not hesitate to contact us and tell us the features you want and the equipment you need to have. We will send you the offers that tick the most features and are available for sale at the moment. And if you are a seller looking to trade in your used Gallus EM 280 printing press for a newer model as soon as possible, send us all the important details about the used printing equipment you own and we will make sure that your offer will reach interested buyers.