Global coverage on any transaction

You tell us what equipment you need and we look for it, literally, on a global scale. The same thing happens if you want to sell a machine – there is a good chance that there will be an interested buyer even 3,000 km away from you, but don’t worry, we take care of everything from A to Z. The advantage of activating globally is the shorter time to complete the transaction. If you tell us that you want to sell or buy equipment urgently, we will do our best to fit into the set time frame, and from this point of view, our global coverage helps us.

A professional appraisal of equipment value

Transparency is most important to us, which is why we carry out professional evaluations of the value of the equipment you want to buy or sell. We are experienced in carrying out the evaluation of the value of any used equipment for the printing industry and we can pride ourselves on the fact that no small detail escapes us. In the end, you can be sure that you will get or pay a fair price for the printing press.

Complete services in one place

By using our services, you will benefit from a single point of contact for all your needs regarding the buying and selling of used machinery for the printing industry. You will be in touch with only one person who will handle the transaction, and this makes the whole process much easier. We know how frustrating it can be to be redirected from one department to another to find an answer to a question. We assure you that you will not have such an experience if you work with us.

Solutions for any problem

We have experience in the field, and that helps us overcome any obstacle more easily. Any technical or logistical problem that arises, we already have a solution. This helps the client to be much more relaxed and confident in the finality of the process. Of course, we discuss with the customer any problem that arises and show them the solutions we have. Don’t forget that we are more than just service providers, we are your partners.

Flexibility and adaptability to customer needs

One thing that the clients we have worked with appreciate is the degree of flexibility and adaptability we have when it comes to their needs. We are involved in every transaction 100%, we listen to our customers and find the best solutions for their requirements. This is also the reason why we ask for so much detail in collaboration, we want to know and understand every need of the client. Sometimes, along the way, we even discover new needs of the client, without him knowing that he has them.

Versatility

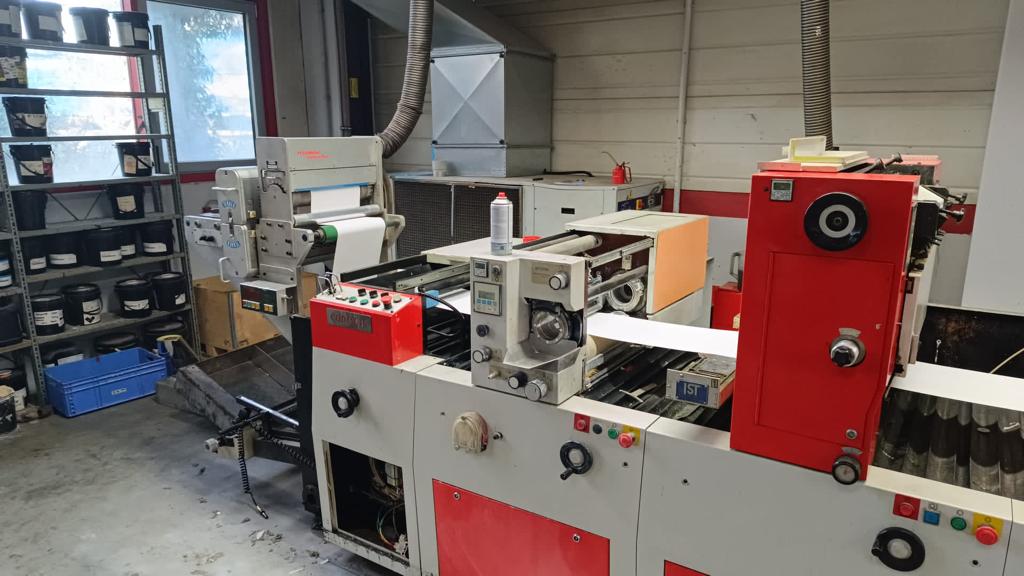

We know almost every type of used machine or equipment from around the world and have worked overtime with machines made by world-renowned manufacturers such as Heidelberg, Muller Martini, Bobst, Kolbus, Man Roland, or KBA. Flat offset printing equipment, digital printing equipment, flexographic printing equipment, screen printing equipment, guillotines, laminating equipment, stamping equipment, book sewing machines, etc. have passed through our hands.